2 min read

Process improvement tasks and objectives

There are many reasons why a company may pursue continuous improvement projects: teams may be tasked with identifying...

Your customers have specifications to meet, problems to solve, end users to satisfy, and timelines to hit. They come to you with a set of questions to determine if your staff, machines, and facilities can deliver what they need. Your ability to answer those questions and make products to meet their needs allows you to succeed. When you choose a manufacturer of cutting tools, consider asking some of the same questions those customers ask you.

How Do You Ensure Repeatability?

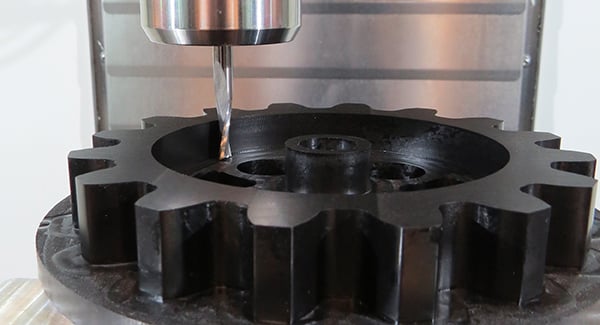

Look for a manufacturer that consistently produces high-quality cutting tools that are the same every time you order. Your precision machining work might require material-specific tool geometries and/or coatings. You need to be certain that the manufacturer you work with can accomplish the task every time without any variations. Look for a manufacturer that does in-house coating; this will help ensure quality expectations and save you time.

How Quickly Can You Deliver Tools?

You can’t always plan ahead with your tool inventory needs; sometimes you need tools quickly. Look for a cutting tool maker that can deliver standard tools within days and most custom tools in two weeks or less. This is where working with a US-based tool manufacturer can be a significant advantage.

Can You Manage Both Small Quantity and High Volume Production?

A cutting tool manufacturer that has a wide range of on-site manufacturing will be more flexible with tool design, quantity breaks, capacity, and lead times. When establishing a new product line, consider whether the manufacturer can seamlessly help you make the transition from prototype to full-scale production. If you can find a manufacturer that is small enough to create the prototype tools you need, and large enough to produce a volume order of those tools, you’ll be better able to meet your demanding production schedules.

How Do You Help Solve Problems?

Look for a manufacturer that understands not only your precision machining business but also the specific materials you work with. When a cutting tool manufacturer knows your goals for tool performance and understands the potential problems you might face machining different materials, that manufacturer can help improve individual operations and your business performance. Ask if a tool manufacturer can support continuous improvement efforts you are undertaking.

Ready to Talk Cutting Tools?

MITGI is ready to talk about your cutting tool needs. We’ve been asked these and other questions, and we designed our business to be helpful in solving unique challenges for other manufacturers. Contact us and learn if we can provide the high-quality tools and support you need.

Aug 20, 2025by MITGI

There are many reasons why a company may pursue continuous improvement projects: teams may be tasked with identifying...

Aug 13, 2025by MITGI

In many industries that require precision machining, burrs left behind during manufacturing can get in the way of the...

Mar 31, 2025by MITGI

For long-running product lines with well-established cutting tool usage, blanket orders are an easy way to ensure that...