2 min read

Process improvement tasks and objectives

There are many reasons why a company may pursue continuous improvement projects: teams may be tasked with identifying...

By: Jennie Gordienko on Nov 3, 2020 1:32:00 PM

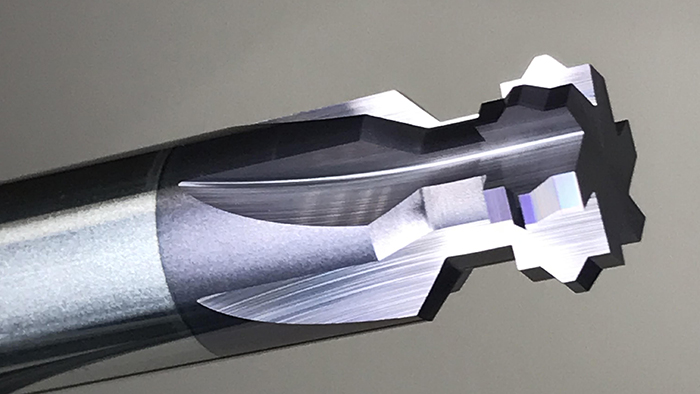

Nearly every company we work with has goals tied to continuous improvement. For some that means reducing cycle times on a specific project. For others it means increasing tool life on a long-running job to create significant cost savings throughout the life of the product. In some cases, companies may need to improve tool performance so that fewer operations are needed.

MITGI works with companies every day to help identify the exact needs at hand and offers ways to achieve the goals through cutting tools.

Recently we worked with a medical device manufacturer that was tasked with reducing cycle times during the initial scale-up for production. Learn more about the project and approach >>

Aug 20, 2025by MITGI

There are many reasons why a company may pursue continuous improvement projects: teams may be tasked with identifying...

Aug 13, 2025by MITGI

In many industries that require precision machining, burrs left behind during manufacturing can get in the way of the...

Mar 31, 2025by MITGI

For long-running product lines with well-established cutting tool usage, blanket orders are an easy way to ensure that...