2 min read

Process improvement tasks and objectives

There are many reasons why a company may pursue continuous improvement projects: teams may be tasked with identifying...

There are many reasons why a company may pursue continuous improvement projects: teams may be tasked with identifying cost savings; increases in demand may drive the need for greater throughput; long-running jobs may need review to ensure that they remain profitable over time. Any of all of these reasons may be enough to justify the resources and time to identify potential areas of improvement.

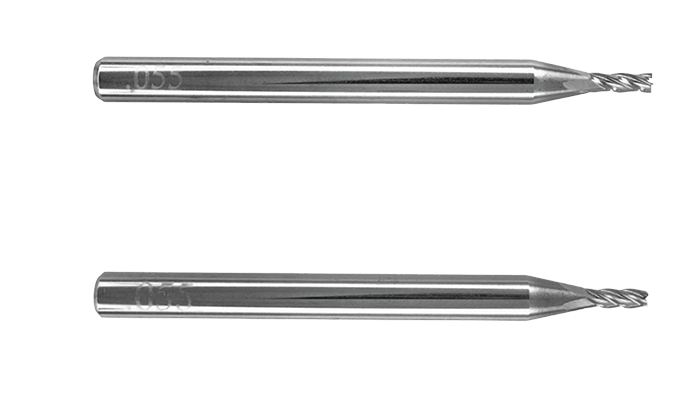

MITGI works with a lot of teams tasked with improving cutting tool efficiencies and performance. Here are some common process improvement tasks and objectives we’ve observed:

If your team is tasked with process or continuous improvement projects, consider tool changes that may help you to achieve your goals. Contact MITGI to start discussing your project today.

Aug 20, 2025by MITGI

There are many reasons why a company may pursue continuous improvement projects: teams may be tasked with identifying...

Aug 13, 2025by MITGI

In many industries that require precision machining, burrs left behind during manufacturing can get in the way of the...

Mar 31, 2025by MITGI

For long-running product lines with well-established cutting tool usage, blanket orders are an easy way to ensure that...