2 min read

Process improvement tasks and objectives

There are many reasons why a company may pursue continuous improvement projects: teams may be tasked with identifying...

Undercutting is considered one of the more challenging operations a machinist will face, and that makes proper tool selection even more important.

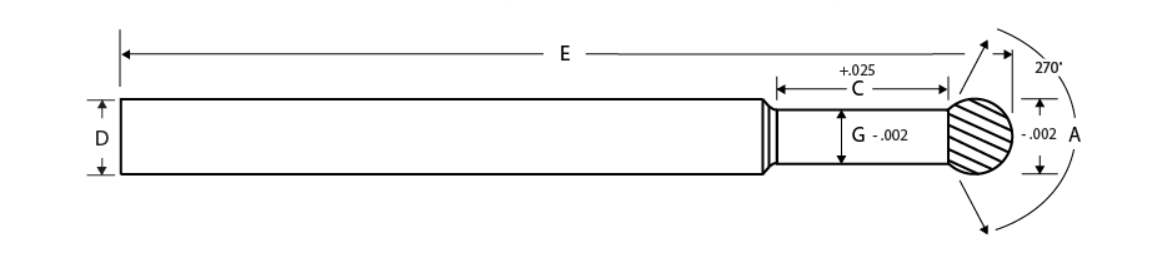

Using an undercutting end mill, often called a lollipop or cherry ball tool because of the tool’s semi-spherical head, allows you to machine slots, ports, unique contours, and rounded edges into material. The term “undercut” is used because these tools allow a machine to cut on the underside of material. To execute that undercut, the cherry ball cutting surface must be larger than the neck of the tool—like a lollipop.

An undercutting end mill can be the best choice to cut a channel into material for fluid flow. MITGI makes cherry ball cutters that can machine a path to your specifications, including the polished finish needed for fluid movement. Whether for products used in medical devices, for fuel delivery, or for lubrication needs, these channels require precise manufacturing and a tool like an undercutting end mill.

MITGI’s standard undercutting end mills are designed with a wrap angle of 270 degrees—that’s the arc of the cherry ball measured from one side of the tool’s neck to the opposite side. That design allows the undercut.

When looking for ways to increase parts per tool, lower our overall tool costs, or achieve a tighter tolerance you should consider a custom tool for your operation. For undercutting end mills, there are custom options available to achieve specific shapes or angles.

Another option is adding a special coating to your end mills. Selecting a coating based on the material you’re cutting is a quick way to improve tool performance. If you have any questions or would like guidance in this area, please reach out to MITGI.

Aug 20, 2025by MITGI

There are many reasons why a company may pursue continuous improvement projects: teams may be tasked with identifying...

Aug 13, 2025by MITGI

In many industries that require precision machining, burrs left behind during manufacturing can get in the way of the...

Mar 31, 2025by MITGI

For long-running product lines with well-established cutting tool usage, blanket orders are an easy way to ensure that...