2 min read

Process improvement tasks and objectives

There are many reasons why a company may pursue continuous improvement projects: teams may be tasked with identifying...

Every machinist knows the importance of chip control and just how easy it is to take for granted when it’s working well. When it isn’t, it can be a real headache until a solution is found. Luckily, there are many options to consider that could help alleviate chip-related issues: helix modifications, chip breakers, using coolant to remove chips, optimizing the geometry for chip load, and many more. Working with a cutting tool manufacturer allows customers to choose the option that works best for the job and materials at hand.

How does this play out?

Application: COMPANY A is a firearms manufacturer and needs a tool to create a thin-walled slot

Material: Steel

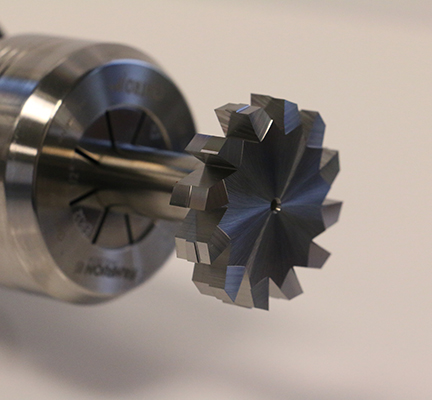

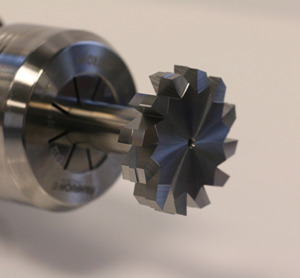

Tool type: Custom form keyseat cutter

Coating: None

MITGI mix:

Add-on Request: COMPANY A would like to increase tool life thereby reducing overall project costs

MITGI recommendation: Add more teeth to the form. With more teeth to engage, the tool life will increase resulting in reduced tool quantities over the life of the job.

Application: COMPANY B specializes in hydraulic components; facing tight time constraints, COMPANY B is creating a tapered form and places high priority on part finish

Material: Aluminum

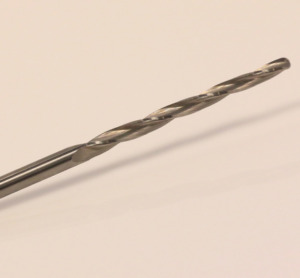

Tool type: Custom tapered reamer

Coating: None

MITGI mix:

Want to schedule a time to meet with our team? We’re adept at working remotely to handle questions, troubleshoot technical issues, and discuss new ideas. We’re available by phone, email, ZOOM, Skype, and Microsoft Teams. Contact us today or book an appointment for you and your team.

Aug 20, 2025by MITGI

There are many reasons why a company may pursue continuous improvement projects: teams may be tasked with identifying...

Aug 13, 2025by MITGI

In many industries that require precision machining, burrs left behind during manufacturing can get in the way of the...

Mar 31, 2025by MITGI

For long-running product lines with well-established cutting tool usage, blanket orders are an easy way to ensure that...